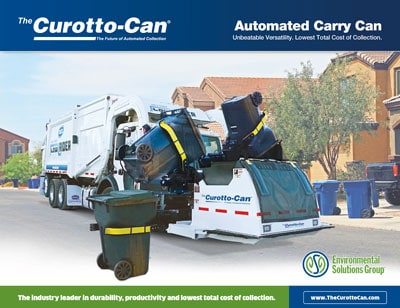

The Curotto-Can® has the fastest load time of any automated system on the market and delivers a proven 25% to 30% productivity advantage over automated side loaders. By using the robust reliability of a front loader, this carry can delivers game-changing performance that will enable you to service more customers, more quickly, in more applications.

- Fastest load time – 4-5 seconds from wheel-stop-to-wheel-go

- Radically more maneuverable – 25% faster around cul-de-sacs

- No prox or limit switches and no logic and/or driver cards

- Eliminates cost of cart loss and damage

- Maintenance and repair done with both feet on the ground

- Utilizes the robust reliability of the front loader platform

- Eyes-always-forward operation – no looking backward to service a cart

- Operators can preview material before it is packed

- Hopper is 4x larger than ASL (capable of taking large bulk)

- Loads bulk material like a rear loader (eliminates chase vehicle)

- Can be used as a commercial front loader without compromise

- Fewer pack cycles mean greatly reduced hopper floor wear

The Curotto-Can Advantage

Arm-Forward Increases Collection Efficiencies

The key factor in residential productivity is how long a truck is stopped in front of a house for service. The longer the loading cycle the lower the productivity. With a front loader equipped with a Curotto-Can automated carry can, stop time (as measured from wheel stop to wheel go) is 4-5 seconds as compared to 12-18 seconds for an ASL.

Compare The Curotto-Can To An ASL

Automated Side Loader

Does 10 services @ 12 seconds per cycle

= 120 SECONDS PER 10 STOPS

ASL pack cycles per day – 3,000 PLUS

(Lots of wear and tear)

The Curotto-Can

Does 10 services @ 5 seconds + 20 second arm/fork cycle

= 70 SECONDS PER 10 STOPS

Curotto-Can pack cycles per day – 90-100

(Less wear and tear)

THE CUROTTO-CAN IS THE PRODUCTIVITY LEADER

Idling and packing are big fuel burners. The example above illustrates the idling advantage of the Curotto-Can. ASLs continuously pack, putting the engine under load during the entire route. The Curotto-Can system packs once per hopper dump.

Less packing and idling = lower fuel consumption (up to 20% lower in an independent comparison).

REDUCE CART COSTS (from loss or damage)

Consider what you spend on carts. Cart loss and damage are accepted as the cost of doing business with automation. It doesn’t have to be. The Curotto-Can automated carry can never packs carts. If a cart drops into the container hopper, the operator can simply and safely remove it. The Curotto-Can dumps carts much lower and with a much smoother action than ASLs. This means fewer damaged lids, wheels, and axles. The unique gripper design ensures no metal contacts the cart while gently applying pressure to the cart body, resulting in extended cart life. Costs from cart damage with the Curotto-Can automated carry can will go to near zero.

GREATER MANEUVERABILITY

Because the arm is forward of the cab and steer axle it behaves like a boom. This unique feature enables the Curotto-Can to easily move around parked cars and cul-de-sacs – up to 20% faster in an independent comparison. Better maneuverability means fewer backing events resulting in improved productivity and enhanced safety.

AFL MEANS SAFETY

The Curotto-Can is the only automated system that provides an “Eyes-Forward” working environment and results in improved operator and public safety. Drivers aren’t required to “rubberneck” 1,000 times a day, in contrast to ASLs, drastically reducing Repetitive Stress Injury risk. Eyes-Forward collection improves driver awareness and focus, reducing the chance of personal property damage (mailboxes etc) and general public injury due to driver error. These inherent safety benefits combined with fewer backing events make a front loader equipped with a Curotto-Can THE choice for automation.

CONTAMINATION MITIGATION

The Curotto-Can is the only automated system that allows the driver to see material before it’s packed. You can stop contamination in any stream at its source – the curb. Identifying and safely removing contamination while recording violations ensures clean waste streams. Curotto-Can users enjoy contamination rates as low a 4% while communities using ASLs suffer 25% contamination. Collecting clean material is a major cost avoidance and mitigates the risk of culling, handling, and disposing of contamination.

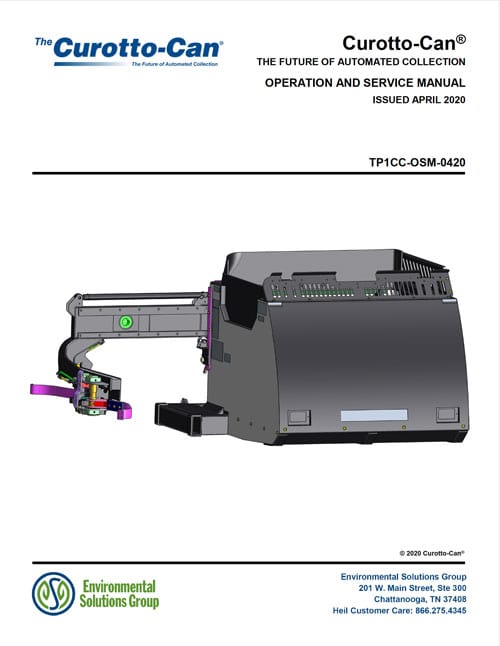

Utilizes The Front Loader Platform

The key factor in residential productivity is how long a truck is stopped in front of a house for service. The longer the loading cycle the lower the productivity. With a front loader equipped with a Curotto-Can, stop time (as measured from wheel stop to wheel go) is 4-5 seconds as compared to 12-14 seconds for an ASL. Compare:

Payload Leader

Simple math: more load capacity means fewer trips to the landfill! On average, ASLs have a capacity of a little over 30 cubic yards. By comparison, front loaders have a massive 12-cubic-yard hopper plus a 28 to 32-cubic-yard body. With a 40-44 yard body, this means more payload and fewer trips to the landfill or transfer station. With single-stream routes, this means more room for recycling, as recycling is more volume-based versus waste-based.

Fleet Optimization / Fleet Standardization

Front-loaders have a track record of robust construction and proven reliability, durability, and uptime. Standardizing your fleet with the Curotto-Can system provides operational flexibility with fewer collection vehicle models to maintain. Instead of having a mixture of ASL’s and commercial front loaders, this allows for one front loader platform to collect both commercial and residential. It can handle cleanups, bulk collection, commercial collection, single-stream routes, and green waste. Given the flexibility of the Curotto-Can, rear loaders and drop frame side loaders are deemed obsolete, saving fleet owners from maintaining costly spares.

Low-Lift Loading Height Means No Chasing The Route

A huge benefit of the Curotto-Can is its ability to handle “take-all” routes. Unlike most automated side loaders, the Curotto-Can – and its low-lift loading height makes loading mattresses, couches, etc., as easy as a drop-frame side loader, but allows for much higher productivity – due to the speed of the Curotto-Can automated arm. And unlike any side loader, the driver’s eyes are always focused in front of the vehicle, making it the safest refuse collection vehicle offered today.

A Host of Add-On Options Available

The Curotto-Can system offers a multitude of add-on options to provide even greater versatility and efficiency. Some of our most popular options include:

- Autocover

- Single Point Lubrication System

- Brush Kit / Hopper Seal

- Work Lamps

- Curb Access Controls

- Spacer Kits

- Dual Controls

- Conspicuity Tape

- 6″ and 8″ Belts Upgrade Kits

Want To Learn More About The Curotto Can Advantages?

Learn More HereHave Questions? No problem, we are here to help.

We're Here To TalkHaving trouble with your Curotto-Can automated carry can?

Some of the most common troubleshooting procedures are included in the links below. As always, you can also call 866-310-4345 for assistance.

- Old style gravity latch check and adjustment

- Modifying the dogbone assembly either when there is interference between the link bar and the dogbone or when installing the new style link bar

- Rexroth valve (main hydraulic valve) cleaning procedure

- Top plate (of dogbone) modification to allow the bearing buddy sufficient space to avoid binding with the plate

- Overview of the auto-retract system – includes information on what parts of the system to check when there are problems

- Grip function port relief sandwich valve installation

- Link bar installation and adjustment procedure

- New style gravity hinge installation procedure

- Adding a second joystick

Take Your Collection Safety And Efficiency To The Next Level

The most productive and profitable refuse fleets have found that utilizing the Curotto-Can automated frontload collection provides unbeatable safety and efficiency. If you are looking to improve your bottom line, discover how Curotto-Can will deliver the lowest cost to dump that can.